Service Details

519 740 7600

Service Details

Field Services from Fan Dynamics Are Extensive!!

Over the decades Fan Dynamics has serviced many, many types of industries and companies. During that time we have solved an unlimited number of fan servicing issues. When a fan problem develops, our qualified technical staff get it back in service quickly. If it is critical to your system or operations, we work around the clock to get the fan up and running properly. Our most common servicing options are detailed below.

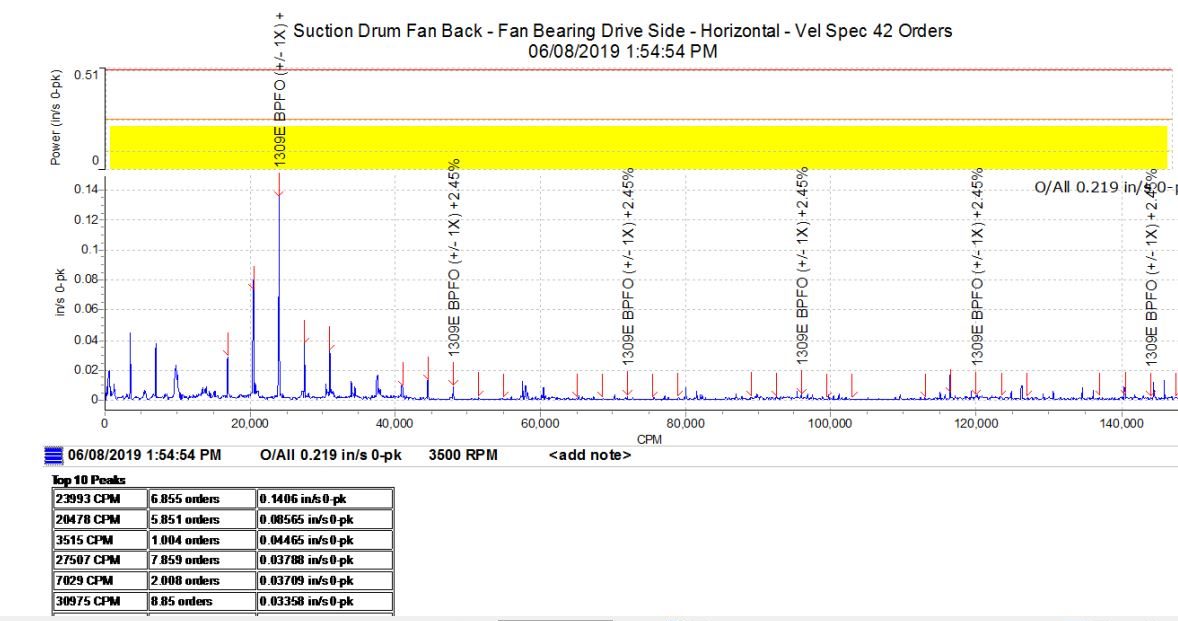

Vibration Analysis

Experienced, certified analysts, with modern equipment and up-to-date software, will examine your equipment and record vibration data from bearing points. The data will be analyzed for many conditions including bearing faults, imbalance, misalignment, aerodynamic forces, gear frequencies, AC induction motor faults, and belt drive problems. An actual example of a printout from our equipment is shown below.

Fan Refurbishment

Older fans were built bigger, stronger and run at slower speeds. They just need a refresh to be as good as new. Replacing wear items like bearings, motors and v-belt drives with a clean up and fresh paint will increase the lifespan for another 20-30 years.

Impeller Balancing

Using up-to-date field balancing machines, accurate single or multi-plane balances can be performed in situ, to meet the most demanding criteria. If limited access makes in situ balancing impossible, impellers can be removed for shop balancing to the required tolerances.

Replacement and Retrofit of Fan Components

When fan parts such as bearings, shafts, impellers, and motors fail or wear out, Fan Dynamics has both service staff and parts to repair them quickly.

Commissioning of Fan Equipment

When special field inspection, adjustment, and supervision is required to commission a fan, we see to it that all steps have been carried out. Fan Dynamics will ensure the proper installation and start-up of the fan and will make certain that it is functioning as designed.

Laser Shaft Alignment

Proper shaft alignment is one of the most important factors influencing rotating equipment performance, including from a lubrication perspective.

Misaligned shafts can generate excessive forces during equipment operation that place significant stress on the rotating components. These same forces can also place more stress on the lubricant. If too severe, these forces can reduce the lubricant’s film thickness, which can, in turn, lead to accelerated wear and component degradation from sustained metal-to-metal contact.

Installation of Motor Shaft Grounding Brush

Currents due to shaft voltage causes deterioration of motor bearings, but can be prevented with a grounding brush on the shaft, grounding of the motor frame, insulation of the bearing supports, or shielding. Shaft voltage can be induced by non-symmetrical magnetic fields of the motor (or generator) itself.

Preventive Maintenance

A preventive maintenance program should be considered when the consequences for risks of fan breakdowns out weight the cost of the program. Each application is different and should be reviewed as to the type of program warranted. Fan Dynamics staff will assist you in this analysis. We will custom tailor the program to fit the equipment and match your schedule.

Preventive Maintenance: Why Bother?

- On critical installations, it is disruptive, costly and sometimes dangerous to have a fan go down without warning.

- With scheduled maintenance, fan components subject to wear can be closely monitored and changed out at the end of their useful life, prior to total failure. Without maintenance, components fail, often resulting in additional fan damage.

- A planned maintenance program can be scheduled to coincide with low demand periods. Breakdowns, on the other hand, must be repaired when they occur, regardless of demand.

- Equipment vibration analysis is recommended in the preventive maintenance program to detect bearing problems or other faults before they occur. This can be done using our FFT Spectrum Analyzer and logger. The comparison of bearing signatures, over time, gives reliable quantitative data on wear and expected life. The result is increased bearing life without the risk of failure.